Industrial environments and laboratory settings frequently encounter situations where protective equipment becomes contaminated with hazardous substances. Among the various protective gear used in these environments, waterproof PPE tablecloths serve as critical barriers against chemical spills and contamination. When these protective covers become exposed to strong chemicals, proper handling becomes paramount to ensure workplace safety and environmental compliance. This comprehensive guide explores four essential solutions for effectively managing waterproof PPE tablecloths that have been contaminated with aggressive chemical agents.

Industrial environments and laboratory settings frequently encounter situations where protective equipment becomes contaminated with hazardous substances. Among the various protective gear used in these environments, waterproof PPE tablecloths serve as critical barriers against chemical spills and contamination. When these protective covers become exposed to strong chemicals, proper handling becomes paramount to ensure workplace safety and environmental compliance. This comprehensive guide explores four essential solutions for effectively managing waterproof PPE tablecloths that have been contaminated with aggressive chemical agents.

Understanding Waterproof PPE Tablecloths and Chemical Contamination Risks

Waterproof PPE tablecloths represent specialized protective equipment designed to create impermeable barriers in work environments where chemical exposure poses significant risks. These protective covers are manufactured from advanced materials that resist liquid penetration while maintaining durability under harsh conditions. The primary function of waterproof PPE tablecloths extends beyond simple surface protection to include preventing cross-contamination, protecting workers from direct chemical contact, and containing spills before they spread to larger areas.

Chemical contamination of waterproof PPE tablecloths occurs when strong acids, bases, solvents, or other hazardous substances come into contact with the protective surface. The severity of contamination depends on multiple factors including the chemical concentration, exposure duration, and the specific material composition of the tablecloth. Strong chemicals can potentially degrade the waterproof coating, compromise the structural integrity, or create residual contamination that persists even after visible cleaning. Understanding these risks forms the foundation for implementing appropriate handling procedures.

The consequences of improperly managed contaminated waterproof PPE tablecloths extend to worker safety, environmental protection, and regulatory compliance. Workers handling contaminated materials without proper procedures risk chemical burns, respiratory exposure, and long-term health effects. Environmental contamination can result from improper disposal or inadequate decontamination processes. Additionally, organizations must maintain compliance with occupational safety regulations and environmental protection standards governing hazardous material handling.

Solution One: Immediate Isolation and Assessment Protocol for Contaminated Waterproof PPE Tablecloths

The first critical solution when dealing with chemically contaminated waterproof PPE tablecloths involves implementing an immediate isolation and assessment protocol. This systematic approach begins the moment contamination is identified and establishes the framework for all subsequent handling procedures. Speed and precision in this initial phase significantly influence the overall success of contamination management.

Upon discovering that waterproof PPE tablecloths have been exposed to strong chemicals, the immediate priority involves isolating the contaminated material from the active work environment. This isolation prevents additional exposure to personnel and limits the potential for cross-contamination to other equipment or surfaces. The contaminated waterproof PPE tablecloths should be carefully removed from their current location using appropriate personal protective equipment, including chemical-resistant gloves, face shields, and protective garments suitable for the specific chemical involved.

The assessment phase requires detailed documentation of the contamination incident. Essential information includes identifying the specific chemicals involved, estimating the volume of chemical exposure, noting the duration of contact, and observing any visible damage to the waterproof PPE tablecloths. This documentation serves multiple purposes including guiding the selection of appropriate decontamination methods, providing information for regulatory reporting if required, and offering insights for preventing future contamination incidents.

Creating a designated contamination zone specifically for handling affected waterproof PPE tablecloths establishes controlled conditions for further processing. This zone should feature adequate ventilation, secondary containment systems to capture any dripping or off-gassing chemicals, and clear signage warning personnel of the hazardous materials present. The contamination zone should remain separate from clean work areas and equipped with emergency response equipment including eyewash stations, safety showers, and spill containment materials.

During the assessment phase, determining whether the contaminated waterproof PPE tablecloths can be decontaminated and reused or must be disposed of as hazardous waste represents a critical decision point. Factors influencing this determination include the extent of chemical penetration, the presence of visible damage such as holes or degraded waterproofing, the compatibility of decontamination methods with the tablecloth material, and regulatory requirements specific to the chemical involved. Some strong chemicals may render the waterproof PPE tablecloths unsuitable for continued use regardless of decontamination efforts.

Solution Two: Advanced Decontamination Procedures for Waterproof PPE Tablecloths

When assessment determines that contaminated waterproof PPE tablecloths are candidates for decontamination rather than immediate disposal, implementing advanced decontamination procedures becomes the second essential solution. These procedures must neutralize chemical hazards while preserving the functional integrity of the protective equipment to the greatest extent possible.

The decontamination process for waterproof PPE tablecloths begins with preliminary gross decontamination to remove bulk chemical contamination. This initial step typically involves carefully scraping or blotting excess chemical material from the surface using disposable absorbent materials. The goal is reducing the chemical load before introducing water or decontamination solutions, which could potentially spread contamination over a larger area. All materials used in gross decontamination must be treated as hazardous waste and disposed of according to applicable regulations.

Chemical-specific decontamination methods must be selected based on the properties of the contaminating agent and its interaction with the waterproof PPE tablecloths material. For acidic contamination, careful neutralization using appropriate alkaline solutions may be employed, followed by thorough rinsing. Conversely, basic chemical contamination requires neutralization with suitable acidic compounds. Organic solvents may necessitate different approaches such as sequential washing with compatible cleaning agents or specialized decontamination solutions designed for the specific chemical family involved.

The physical washing process for waterproof PPE tablecloths requires careful attention to technique and thoroughness. High-pressure water washing can effectively remove residual contamination from the waterproof surface, but the pressure must be calibrated to avoid damaging the material or forcing chemicals deeper into any existing pores or damage points. Temperature considerations also factor into effective decontamination, as some chemical residues respond better to warm water washing while others require cold water to prevent chemical reactions or vapor release.

Multiple wash cycles with appropriate decontamination agents followed by comprehensive rinsing represent best practices for thorough decontamination of waterproof PPE tablecloths. Each wash cycle should be conducted in a dedicated decontamination area with proper containment for wash water, which becomes contaminated during the process and requires treatment as hazardous waste. The number of wash cycles depends on the severity of contamination and the results of verification testing.

Verification testing provides objective evidence that decontamination efforts have successfully reduced chemical residues to safe levels on waterproof PPE tablecloths. Testing methods range from simple colorimetric tests for certain chemicals to sophisticated analytical techniques including spectroscopy or chromatography for detecting trace contamination. The selected verification method must be appropriate for the specific chemical involved and sensitive enough to detect residues at concentrations that could pose risks during subsequent use.

After successful decontamination and verification, the waterproof PPE tablecloths must undergo careful inspection for any damage that might compromise their protective function. Even if chemical residues have been removed, physical damage such as tears, punctures, or degraded waterproof coatings renders the equipment unsuitable for continued use. Documentation of the decontamination process, verification results, and post-decontamination inspection findings creates an essential record for quality assurance and regulatory compliance purposes.

Solution Three: Proper Disposal Methods for Irreversibly Contaminated Waterproof PPE Tablecloths

When contaminated waterproof PPE tablecloths cannot be adequately decontaminated due to the nature of the chemical exposure, the extent of damage, or regulatory restrictions on reuse, proper disposal becomes the third critical solution. Hazardous waste disposal requires strict adherence to environmental regulations and workplace safety protocols to protect both human health and the environment from the risks posed by chemically contaminated materials.

Characterizing the contaminated waterproof PPE tablecloths as hazardous waste begins with identifying the specific waste characteristics based on the contaminating chemicals. Regulatory frameworks classify hazardous waste according to properties such as ignitability, corrosivity, reactivity, and toxicity. The contaminating chemical’s properties determine the waste classification, which in turn dictates the specific handling, packaging, labeling, and disposal requirements that must be followed. Accurate waste characterization forms the legal and practical foundation for all subsequent disposal activities.

Packaging contaminated waterproof PPE tablecloths for disposal requires containers that are compatible with the chemical residues present and meet regulatory specifications for hazardous waste containment. The containers must be constructed of materials that resist degradation by the chemical residues and feature closures that prevent leakage during storage and transportation. Overpacking contaminated waterproof PPE tablecloths in secondary containers provides additional protection against accidental release and facilitates handling of materials that have absorbed liquid chemicals or retained wetness from decontamination attempts.

Proper labeling of packaged contaminated waterproof PPE tablecloths represents a critical safety and regulatory requirement. Labels must clearly identify the contents as hazardous waste, specify the chemical constituents or waste characteristics, provide hazard warnings appropriate to the chemicals involved, and include the accumulation start date to track storage time limits. Additional marking requirements may apply based on the quantity of waste accumulated and specific transportation regulations if the waste will be shipped off-site for disposal.

Temporary storage of containerized contaminated waterproof PPE tablecloths pending disposal must occur in designated hazardous waste accumulation areas that meet regulatory requirements for secondary containment, weather protection, and security against unauthorized access. Storage time limits vary depending on waste generator status and the specific regulatory jurisdiction, but most facilities must arrange for disposal within specified timeframes to avoid violations. The storage area should be regularly inspected for container integrity, proper labeling, and any signs of leakage or degradation.

Selecting an appropriate disposal facility for contaminated waterproof PPE tablecloths requires verification that the facility is properly permitted to handle the specific waste types being disposed of and employs disposal methods appropriate for the chemical constituents present. Treatment methods may include incineration for organic chemical contamination, chemical treatment for certain inorganic compounds, or secure landfill disposal for stabilized wastes. The disposal facility should provide documentation confirming proper disposal, which becomes part of the organization’s hazardous waste management records.

Transportation of contaminated waterproof PPE tablecloths to disposal facilities must comply with hazardous materials transportation regulations governing packaging, labeling, marking, placarding, and documentation. Organizations generating hazardous waste may need to engage licensed hazardous waste transporters who possess the necessary permits, training, and equipment to safely move the materials. Maintaining detailed shipping documentation creates an auditable trail demonstrating regulatory compliance and proper stewardship of hazardous materials from generation through final disposal.

Solution Four: Preventive Strategies and Enhanced Protocols for Waterproof PPE Tablecloths Management

The fourth essential solution focuses on implementing preventive strategies and enhanced protocols that reduce the likelihood and severity of chemical contamination incidents involving waterproof PPE tablecloths. While reactive solutions address contamination after it occurs, proactive prevention represents the most effective approach to managing risks associated with strong chemical exposure in workplace environments.

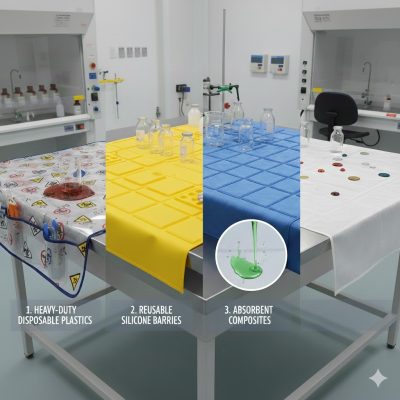

Selecting appropriate waterproof PPE tablecloths for specific chemical environments constitutes the foundation of preventive protection. Not all waterproof materials offer equivalent resistance to different chemical classes. Conducting compatibility assessments between the anticipated chemical exposures and the material composition of waterproof PPE tablecloths ensures that selected equipment provides adequate protection for the intended application.

Manufacturers typically provide chemical resistance data indicating how specific materials perform when exposed to various chemicals, including breakthrough times and degradation characteristics. Matching waterproof PPE tablecloths to the specific chemicals present in the work environment maximizes protective performance and extends usable life.

Implementing proper use protocols for waterproof PPE tablecloths significantly reduces contamination incidents and improves overall effectiveness. Training programs should educate workers on correct deployment techniques, appropriate positioning relative to chemical work areas, and recognition of signs indicating that replacement is needed. Workers should understand that waterproof PPE tablecloths serve as sacrificial barriers designed to protect other surfaces and equipment, meaning they should be considered consumed items after significant chemical exposure rather than permanent equipment requiring decontamination.

Clear protocols should define when waterproof PPE tablecloths must be changed during ongoing work activities, particularly during procedures involving successive chemical steps or when transitioning between different chemical systems.

Regular inspection schedules for in-use waterproof PPE tablecloths enable early detection of degradation, damage, or contamination before problems escalate to serious incidents. Visual inspections should look for signs including discoloration that might indicate chemical absorption, changes in texture or flexibility suggesting material degradation, and physical damage such as tears or punctures that compromise waterproof integrity.

Implementing inspection checklists and documentation systems ensures consistent evaluation and creates records demonstrating due diligence in equipment management. Waterproof PPE tablecloths showing any signs of degradation or damage should be immediately removed from service and properly disposed of before failure occurs during critical operations.

Engineering controls that minimize chemical contact with waterproof PPE tablecloths represent highly effective prevention strategies. Implementing primary containment systems such as trays, berms, or specialized workstations reduces the likelihood that chemical spills or splashes will contaminate tablecloth surfaces.

Upgrading ventilation systems to better control chemical vapors decreases the potential for condensation of airborne chemicals onto horizontal surfaces. Modifying work procedures to minimize the need for open chemical handling or to relocate particularly hazardous operations to dedicated contained spaces reduces overall exposure risks for all protective equipment including waterproof PPE tablecloths.

Establishing inventory management systems for waterproof PPE tablecloths ensures that fresh, undamaged equipment remains available when needed and that older stock does not exceed shelf life limits. Some waterproof materials can degrade over time even without use, particularly when exposed to environmental factors such as ozone, ultraviolet light, or temperature extremes during storage. Rotating stock according to first-in-first-out principles and marking equipment with purchase or manufacture dates prevents inadvertent use of degraded materials. Maintaining adequate inventory levels ensures that waterproof PPE tablecloths can be promptly replaced when contamination occurs without creating pressure to decontaminate equipment that should be disposed of.

Documentation and record-keeping practices create accountability and provide data for continuous improvement of contamination prevention programs. Records should track contamination incidents involving waterproof PPE tablecloths including the circumstances of exposure, chemicals involved, response actions taken, and outcomes achieved. Analyzing this data reveals patterns that may indicate opportunities for improved chemical handling procedures, enhanced training needs, or equipment selection changes. Documentation also demonstrates regulatory compliance and provides evidence of systematic safety management should regulatory inspections or incident investigations occur.

Creating a culture of safety awareness where workers understand their role in preventing contamination and feel empowered to report concerns or suggest improvements enhances the effectiveness of all preventive strategies. Regular safety meetings that discuss recent contamination incidents, near-misses, or successful prevention efforts keep chemical safety prominent in workers’ awareness. Recognition programs that acknowledge individuals or teams who identify hazards or implement successful improvements reinforce the value the organization places on proactive safety management. When workers understand that waterproof PPE tablecloths represent important protective equipment requiring proper care rather than just another workplace supply, they become partners in contamination prevention rather than passive consumers of safety equipment.

Integrating Comprehensive Management Strategies for Waterproof PPE Tablecloths Safety

Successfully managing chemically contaminated waterproof PPE tablecloths requires integrating all four solutions into a comprehensive program that addresses immediate response needs while building long-term prevention capabilities. Each solution component contributes essential elements to overall safety and compliance, but maximum effectiveness emerges when these approaches work together as an interconnected system rather than isolated procedures.

The relationship between immediate isolation protocols and advanced decontamination procedures demonstrates the importance of systematic integration. Thorough documentation during the isolation and assessment phase provides the information necessary to select appropriate decontamination methods and establish success criteria for verification testing. Conversely, feedback from decontamination attempts can reveal patterns suggesting that certain chemicals or exposure scenarios consistently result in contamination that cannot be adequately remediated, pointing toward the need for enhanced prevention strategies or changes in equipment selection.

Proper disposal methods and preventive strategies also connect in important ways. Analyzing disposal records to identify the most frequent causes of waterproof PPE tablecloths contamination that necessitates disposal rather than decontamination highlights opportunities for targeted prevention efforts.

If disposal records show that particular work processes or chemical systems consistently contaminate equipment beyond salvage, implementing engineering controls or procedure modifications for those specific activities may substantially reduce waste generation while improving safety. The financial costs associated with hazardous waste disposal can justify investments in prevention measures that might otherwise seem expensive when evaluated in isolation.

Training programs represent a critical integration point for all four solution components. Comprehensive training should prepare workers to recognize contamination incidents and implement immediate isolation procedures, understand when decontamination is appropriate versus when disposal is necessary, execute proper hazardous waste handling procedures, and apply preventive strategies in their daily work.

Training should be tailored to specific job roles, with detailed technical instruction for personnel responsible for decontamination or waste management decisions and awareness-level training for all workers who may encounter waterproof PPE tablecloths in their work environment. A successful PPE program also aligns with broader occupational safety standards and guidance, such as those recommended by the CDC’s National Institute for Occupational Safety and Health (NIOSH), which emphasizes that protective clothing and ensembles must be part of a comprehensive PPE program including hazard assessment and training.

Quality assurance mechanisms ensure that procedures for handling contaminated waterproof PPE tablecloths are followed consistently and effectively across the organization. Regular audits should evaluate compliance with isolation protocols, review decontamination verification records, inspect hazardous waste accumulation areas, and assess implementation of preventive strategies. Corrective action processes should address identified deficiencies promptly and track implementation of improvements to ensure that problems are actually resolved rather than repeatedly identified without correction. Management review of audit findings and contamination incident trends provides oversight and accountability for the overall program.

Emergency response planning represents another important integration element for comprehensive waterproof PPE tablecloths management. While normal procedures address routine contamination incidents, emergency plans prepare for larger-scale releases, fires, or other situations where contaminated equipment may require rapid handling under challenging conditions. Emergency procedures should address securing contaminated waterproof PPE tablecloths during evacuation scenarios, preventing their involvement in secondary incidents such as fires, and coordinating with emergency responders who may need information about contaminated equipment present in affected areas.

Continuous improvement processes leverage experience gained from contamination incidents and changing conditions to refine management approaches over time. Regular program reviews should consider new chemical hazards introduced into the workplace, changes in regulatory requirements, availability of improved waterproof PPE tablecloths materials or decontamination technologies, and lessons learned from contamination incidents or near-misses. Engaging workers in improvement discussions captures practical insights from those most directly familiar with equipment use and contamination challenges.

Conclusion:

Effective management of chemical-contaminated waterproof PPE tablecloths requires a well-rounded approach that includes rapid response, proper decontamination procedures, safe disposal, and long-term preventive strategies. When these elements are integrated into a unified safety program, organizations can significantly reduce risks, protect workers, and maintain regulatory compliance.

At 8688.vn, we specialize in manufacturing high-quality non-woven products and PPE to meet the diverse needs of healthcare, manufacturing, and real estate sectors. Our product range is designed to be safe, breathable, available in eco-friendly options, and suitable for high-volume use. With competitive wholesale pricing, a stable supply, and expert consultation, 8688.vn is a trusted partner that helps businesses implement effective non-woven solutions.

Visit 8688.vn to explore our full product range and find the right solution for your hygiene, operational, and asset protection needs.