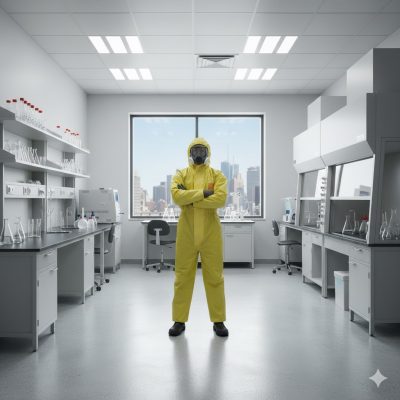

Working in hazardous environments often requires the use of specialized protective equipment that creates unique challenges for workers. Among these challenges, heat stress stands as one of the most critical concerns affecting both safety and productivity. When professionals don protective gear to shield themselves from dangerous chemical exposures, they simultaneously face the physiological burden of elevated body temperatures that can quickly escalate from discomfort to life-threatening conditions.

Working in hazardous environments often requires the use of specialized protective equipment that creates unique challenges for workers. Among these challenges, heat stress stands as one of the most critical concerns affecting both safety and productivity. When professionals don protective gear to shield themselves from dangerous chemical exposures, they simultaneously face the physiological burden of elevated body temperatures that can quickly escalate from discomfort to life-threatening conditions.

The modern workplace demands effective solutions that balance protection with human performance. Understanding the thermal dynamics of protective equipment and implementing strategic cooling approaches has become essential knowledge for safety managers, industrial hygiene professionals, and frontline workers alike. The relationship between chemical protection and thermal comfort represents a complex interplay of material science, human physiology, and environmental factors that requires comprehensive analysis and practical intervention strategies.

Understanding Heat Generation in Chemical Protection Suit Environments

The fundamental challenge of thermal stress begins with the basic design principles of protective equipment. A Chemical Protection Suit functions as a barrier system engineered to prevent harmful substances from contacting the skin or respiratory system. This protective barrier, while essential for safety, creates an enclosed microenvironment that dramatically alters the body’s natural cooling mechanisms. Human beings regulate temperature primarily through perspiration and convective heat transfer, both of which become severely compromised when encapsulated within impermeable materials.

The impermeable nature of a Chemical Protection Suit prevents moisture vapor from escaping, causing sweat to accumulate on the skin surface rather than evaporating. This accumulation eliminates the cooling effect that normally occurs during perspiration, transforming what should be an efficient cooling mechanism into a source of additional discomfort and potential thermal stress. The trapped humidity creates a greenhouse effect within the suit, where body heat continues to build with limited pathways for dissipation.

Physical exertion compounds this thermal challenge exponentially. Tasks performed while wearing protective equipment typically require greater energy expenditure than the same activities conducted in regular clothing. The weight of the equipment itself, combined with restricted movement and reduced visibility, forces workers to expend additional calories. This increased metabolic activity generates more heat precisely when the body’s ability to shed that heat has been dramatically reduced. The result is a rapid escalation in core body temperature that can progress from mild discomfort to heat exhaustion or heat stroke within remarkably short timeframes.

Environmental conditions further influence thermal stress levels. Ambient temperature, humidity, radiant heat sources, and air movement all contribute to the thermal burden experienced by workers. A Chemical Protection Suit worn in a climate-controlled indoor facility presents different challenges than the same equipment used in outdoor summer conditions or near heat-generating industrial processes. Understanding these multifaceted heat sources enables the development of targeted cooling strategies that address specific thermal stressors.

Strategy One: Pre-Cooling Protocols Before Donning Chemical Protection Suit

The concept of thermal banking represents a proactive approach to heat management that begins before workers even don their protective equipment. Pre-cooling protocols aim to lower core body temperature below normal baseline levels, creating a thermal reserve that buffers against the inevitable heat accumulation that occurs during suited work. This strategy recognizes that preventing heat stress is far more effective than attempting to manage it after symptoms have already developed.

Effective pre-cooling can be achieved through multiple methods, each with distinct advantages for different operational contexts. Cold water immersion stands as one of the most effective pre-cooling techniques, with research demonstrating that brief periods in cool water can significantly reduce core temperature. However, the practical limitations of providing immersion facilities at industrial sites make this approach challenging for many organizations. Alternative methods include consuming cold beverages, applying cooling vests or ice packs to key body areas, and spending time in air-conditioned spaces before beginning suited work.

The timing and duration of pre-cooling interventions significantly impact their effectiveness. Studies indicate that pre-cooling benefits are maximized when implemented within thirty minutes of beginning work in a Chemical Protection Suit. The cooling effect diminishes over time, making it essential to coordinate pre-cooling activities with work schedules to capture maximum benefit. For extended operations, combining pre-cooling with periodic cooling breaks creates a comprehensive thermal management approach that maintains worker safety throughout the entire work period.

Hydration status plays a crucial role in pre-cooling effectiveness. The body’s thermoregulatory capacity depends heavily on adequate fluid volume for perspiration and circulatory function. Workers should begin hydrating well before donning protective equipment, consuming fluids at regular intervals in the hours preceding suited work. Cold beverages provide dual benefits by contributing to core cooling while simultaneously ensuring optimal hydration status. However, overconsumption should be avoided, as excessive fluid intake can create discomfort and necessitate restroom breaks that complicate work in sealed protective equipment.

Strategy Two: Selecting Appropriate Chemical Protection Suit Design and Materials

Not all protective equipment creates equal thermal burden. Significant variations exist among different types and designs, with material selection and construction techniques substantially impacting heat stress levels. Understanding these differences enables organizations to select equipment that provides necessary protection while minimizing thermal strain. The goal is matching the level of protection to the specific hazards present, avoiding the use of unnecessarily protective equipment that creates excessive thermal burden without corresponding safety benefits.

The classification system for protective equipment ranges from Level A, providing the highest level of protection, through Level D, offering minimal protection for specific low-hazard situations. Each level incorporates different materials and design features that affect permeability, weight, and thermal properties. A Chemical Protection Suit designated for high-hazard chemical exposure typically utilizes thick, multi-layer materials that provide excellent chemical resistance but also create substantial thermal insulation. Conversely, equipment designed for splash protection or particulate hazards may incorporate lighter, more breathable materials that significantly reduce heat stress while still providing adequate protection for the intended application.

Modern material science has produced innovative fabrics that improve the thermal performance of protective equipment. Some manufacturers now offer materials that incorporate phase-change technology, moisture-wicking properties, or enhanced vapor permeability. These advanced materials attempt to balance chemical protection with improved comfort, though trade-offs inevitably exist. Organizations evaluating protective equipment should consider thermal properties as a key selection criterion, particularly for operations involving sustained use or elevated ambient temperatures.

Proper sizing represents another often-overlooked factor in thermal comfort. An ill-fitting Chemical Protection Suit creates additional thermal stress through multiple mechanisms. Equipment that is too tight restricts movement and compresses the body, generating additional metabolic heat through increased work effort and reduced circulation. Conversely, oversized equipment creates excess material that traps additional air and increases the overall thermal burden. Proper fitting ensures that equipment sits correctly on the body, maximizing whatever limited air circulation is possible while minimizing unnecessary bulk and weight.

Strategy Three: Implementing Strategic Work-Rest Cycles for Chemical Protection Suit Users

The human body possesses remarkable resilience but finite capacity to manage thermal stress. Continuous work in hot conditions eventually overwhelms even the most robust cooling strategies, making scheduled rest periods an essential component of heat management programs. Work-rest cycles systematically alternate periods of heat exposure with recovery intervals, allowing core body temperature to stabilize before heat stress progresses to dangerous levels. The strategic implementation of these cycles can dramatically extend safe working duration while maintaining productivity and protecting worker health.

Determining appropriate work-rest ratios requires consideration of multiple factors including ambient conditions, work intensity, individual worker characteristics, and the specific type of Chemical Protection Suit being used. Various heat stress indices and calculation methods exist to guide this decision-making process, with the most comprehensive approaches integrating environmental measurements, metabolic workload estimates, and clothing insulation values. Generally, more demanding conditions require shorter work periods and longer rest intervals to maintain safe core temperatures.

Rest period effectiveness depends not only on duration but also on the quality of recovery conditions provided. Simply stopping work while remaining suited provides minimal benefit, as the Chemical Protection Suit continues to trap heat even during rest. Optimal recovery requires workers to move to cooler environments and, when safe and practical, to partially or fully remove protective equipment to facilitate heat dissipation. Access to shade, air movement, and cool drinking water during rest periods significantly enhances recovery rates and reduces overall thermal strain.

Monitoring worker physiological responses during work-rest cycles enables real-time adjustment of protocols. Heart rate monitoring, oral temperature measurement, and symptom assessment provide objective data about thermal stress levels. Workers exhibiting elevated physiological indicators or heat stress symptoms should receive extended rest periods before returning to work. This adaptive approach recognizes individual variability in heat tolerance and environmental conditions, creating a flexible system that responds to actual thermal stress rather than relying solely on predetermined schedules.

Strategy Four: Cooling Vest Technology Under Chemical Protection Suit

Wearable cooling technology has emerged as a valuable tool for managing thermal stress in protective equipment applications. Cooling vests represent a practical solution that can be worn beneath a Chemical Protection Suit, providing localized cooling that helps maintain core body temperature within safe ranges. These devices work through various mechanisms including phase-change materials, evaporative cooling, or circulating coolant systems, each offering distinct advantages and limitations for different operational scenarios.

Phase-change cooling vests contain materials that absorb heat as they transition from solid to liquid state, typically utilizing water-ice or specialized gel packs. These vests provide excellent cooling capacity during the phase transition period, effectively removing heat from the torso area where major blood vessels pass close to the body surface. The cooling effect enhances thermoregulation by cooling blood before it circulates to vital organs and the brain. However, phase-change vests have finite cooling duration, typically lasting between one to three hours depending on ambient conditions and activity levels. This limitation makes them most suitable for shorter duration tasks or situations where vests can be recharged during work breaks.

Evaporative cooling vests utilize the principle of evaporation to create a cooling effect, incorporating materials that retain water and allow controlled evaporation. When worn under a Chemical Protection Suit, these vests function somewhat differently than in open air conditions, as the suit’s impermeability limits evaporation rates. Nevertheless, they can still provide beneficial cooling through heat absorption into the moistened fabric. These vests offer the advantage of being lightweight and easily recharged by re-wetting, though their effectiveness is reduced in high-humidity environments and when worn under completely sealed protective equipment.

Circulating coolant systems represent the most sophisticated cooling vest technology, utilizing a small pump to circulate chilled fluid through tubing integrated into a vest garment. These systems provide consistent, controllable cooling that can be adjusted based on thermal stress levels. The cooling duration is limited only by the capacity to maintain coolant temperature, which can be extended through insulated containers or connection to portable cooling units. However, these systems add weight, complexity, and cost compared to simpler passive cooling approaches. They are most appropriate for high-heat environments or extended duration operations where their superior performance justifies the additional complexity.

Strategy Five: Optimizing Hydration and Electrolyte Management for Chemical Protection Suit Wearers

Proper fluid balance represents a cornerstone of heat stress prevention, especially during prolonged work in a Chemical Protection Suit. The human body requires adequate hydration to maintain blood volume, support perspiration, and facilitate heat dissipation through circulatory mechanisms. When wearing a Chemical Protection Suit, fluid losses accelerate due to profuse perspiration, yet replacement becomes challenging because drinking is difficult while fully suited. This creates a precarious situation where workers face rapidly escalating dehydration precisely when maintaining hydration is most critical for thermal regulation and overall physiological function.

Effective hydration strategies begin well before workers don protective equipment. Pre-hydration protocols ensure that workers start with optimal fluid status, providing a buffer against the inevitable fluid losses that occur during Chemical Protection Suit operations. Guidelines typically recommend consuming approximately 500 milliliters of water in the two hours preceding protective equipment use. This pre-hydration should be balanced against the practical reality that excessive fluid intake necessitates urination, which creates significant complications when wearing sealed protective equipment. The goal is achieving optimal hydration without creating discomfort or operational challenges.

During work periods, maintaining hydration becomes more complex when wearing a Chemical Protection Suit that prevents normal drinking. Some Chemical Protection Suit designs incorporate drinking tube systems that allow fluid consumption without breaking the protective seal, though these systems are not universal and may pose contamination risks in certain chemical exposure scenarios. For equipment without integrated hydration systems, workers must rely on scheduled breaks where they can safely remove respiratory protection to consume fluids. The frequency and duration of these hydration breaks should be predetermined based on expected sweat rates, ambient conditions, and work intensity.

Electrolyte replacement deserves equal attention to fluid volume replacement during Chemical Protection Suit use. Perspiration contains significant quantities of sodium, potassium, and other minerals essential for muscle function, nerve transmission, and fluid balance. Prolonged sweating in a Chemical Protection Suit rapidly depletes electrolyte stores, potentially leading to muscle cramps, fatigue, and impaired thermoregulation even when fluid volume is adequately replaced. Sports drinks, electrolyte supplements, or specially formulated heat stress beverages provide necessary mineral replacement. The concentration and composition of these replacement fluids should be selected based on individual sweat rates and the duration of exposure, with longer operations requiring more comprehensive electrolyte management strategies.

Strategy Six: Environmental Controls and Work Area Modification

While personal cooling strategies focus on the individual worker, environmental modifications address thermal stress at its source by reducing the overall heat burden. Creating cooler work environments benefits all personnel and provides a foundational layer of heat stress prevention that complements individual interventions. For operations involving Chemical Protection Suit use, environmental controls may represent the most impactful long-term investment in worker safety and productivity.

Temperature reduction through mechanical cooling systems provides the most direct environmental control in Chemical Protection Suit operations. Industrial air conditioning, portable cooling units, or evaporative coolers can substantially reduce ambient temperatures in enclosed work spaces. Even modest temperature reductions of five to ten degrees Celsius can significantly extend safe work duration and reduce heat stress symptoms for workers required to wear a Chemical Protection Suit. However, cooling entire facilities or outdoor areas may be economically impractical, leading organizations to focus cooling efforts on specific zones such as staging areas, rest spaces, or regions where the most critical or extended suited work occurs.

Ventilation enhancement offers an alternative environmental control strategy, particularly in situations where temperature reduction is not feasible. Increased air movement accelerates convective heat transfer from equipment surfaces and enhances evaporative cooling during rest periods when protective equipment is removed. Industrial fans, ventilation systems, or natural ventilation through building design can improve air circulation. While air movement provides minimal benefit to workers actively wearing a sealed Chemical Protection Suit, it significantly enhances recovery during rest periods and reduces thermal stress for support personnel working in the same environment.

Radiant heat control addresses an often-overlooked source of thermal stress in Chemical Protection Suit work environments. Hot surfaces, industrial processes, or direct sunlight can substantially increase the thermal burden through radiant heat transfer. Shielding workers from radiant sources using barriers, reflective materials, or process modifications reduces this heat input. For outdoor operations involving Chemical Protection Suit use, providing shade structures protects workers during rest periods and staging activities. Even simple interventions like reflective tarps or portable canopies can create noticeably cooler microclimates that enhance recovery and reduce overall thermal stress.

Strategy Seven: Physiological Monitoring and Heat Stress Surveillance Programs

The most sophisticated cooling strategies remain incomplete without systematic monitoring to detect heat stress before it progresses to medical emergencies, particularly during prolonged use of a Chemical Protection Suit. Physiological monitoring programs provide objective data about worker thermal status, enabling timely interventions that prevent heat-related illness. These surveillance systems range from simple symptom checklists to advanced wearable sensor technologies, with the most effective programs layering multiple monitoring approaches to create robust safety nets.

Core body temperature represents the gold standard metric for heat stress assessment, directly measuring the physiological parameter of greatest concern for workers wearing a Chemical Protection Suit. However, obtaining accurate core temperature measurements in field conditions presents challenges. Oral thermometry provides a practical compromise, offering reasonably accurate temperature data that can be quickly obtained during work breaks. Establishing clear temperature thresholds triggers predetermined responses such as extended rest, enhanced cooling measures, or work cessation. A common guideline terminates further work when oral temperature exceeds 38.5 degrees Celsius, though individual variations and acclimatization status may warrant adjustment of these thresholds.

Heart rate monitoring offers a non-invasive alternative or complement to temperature measurement in Chemical Protection Suit operations. Heat stress elevates heart rate as the cardiovascular system works harder to dissipate heat through increased skin blood flow. Wearable heart rate monitors can provide continuous data throughout work periods, alerting supervisors or workers themselves when heart rate exceeds predetermined limits. Recovery heart rate during rest periods provides additional insights into thermal stress levels and recovery adequacy. Workers whose heart rate fails to decline appropriately during rest periods require extended recovery time or removal from heat stress conditions.

Symptom surveillance leverages worker awareness of early heat stress indicators during Chemical Protection Suit use. Structured assessment protocols guide workers and supervisors through systematic evaluation of symptoms including fatigue, dizziness, nausea, headache, excessive sweating, or conversely, reduced sweating despite heat exposure. The buddy system enhances symptom surveillance by training workers to observe colleagues for signs of heat stress that affected individuals might not recognize in themselves. Changes in behavior, coordination, or mental status often signal significant heat stress requiring immediate intervention. Regular communication during work periods, whether through radio systems or visual checks, ensures that developing problems are identified before they escalate to medical emergencies.

Integrating Multiple Cooling Strategies for Optimal Chemical Protection Suit Safety

The most effective thermal management programs recognize that no single intervention provides complete protection against heat stress. Instead, comprehensive safety requires integrating multiple cooling strategies into a cohesive system that addresses thermal stress through complementary mechanisms. This multi-layered approach creates redundancy in protection, ensuring that if one strategy proves inadequate for specific conditions, other interventions continue providing thermal stress reduction.

Successful program development begins with systematic hazard assessment identifying the specific thermal stressors present in each work scenario. Different operations involving a Chemical Protection Suit present unique combinations of ambient conditions, physical demands, equipment characteristics, and exposure durations. Understanding these variables enables selection of the most appropriate cooling strategies for each situation. A comprehensive program might combine pre-cooling protocols, carefully selected equipment, strategic work-rest cycles, cooling vest technology, optimized hydration practices, environmental controls, and physiological monitoring into an integrated system tailored to organizational needs.

Authoritative guidance from the National Institute for Occupational Safety and Health (NIOSH) highlights the importance of layered heat stress controls and worker training when performing tasks in protective clothing, particularly in chemically hazardous environments (see NIOSH Heat Stress guidance:

Training represents a critical but often underemphasized component of effective heat stress prevention. Workers, supervisors, and safety personnel all require education about thermal stress mechanisms, early warning signs, proper use of cooling interventions, and emergency response procedures. Training should emphasize that heat stress prevention is a shared responsibility requiring active participation from all personnel. Workers must understand how to properly use cooling equipment, recognize their own symptoms, and feel empowered to report concerns without fear of negative consequences. Supervisors need skills to implement work-rest schedules, monitor worker status, and make real-time decisions about work continuation or modification based on observed conditions.

Continuous program evaluation and improvement ensures that cooling strategies remain effective as conditions, equipment, or operational demands change. Collecting data about heat stress incidents, near-misses, and environmental conditions enables identification of program weaknesses and opportunities for enhancement. Worker feedback provides valuable insights into the practical effectiveness of interventions and may reveal implementation challenges not apparent to management. Regular program review, ideally conducted annually or after significant incidents, keeps thermal management strategies aligned with best practices and organizational realities.

Conclusion: Advancing Worker Safety Through Comprehensive Thermal Management

Preventing heat stress in Chemical Protection Suit use requires a comprehensive approach that combines physiological knowledge, practical controls, and effective thermal management strategies. These measures help protect worker health while maintaining essential chemical protection.

Thermal management should be treated as a core safety requirement, not an optional upgrade. Investments in cooling solutions, training, and monitoring reduce heat-related illness, improve performance, and enhance worker morale and productivity.

At 8688.vn, we specialize in manufacturing high-quality non-woven products and PPE to meet the diverse needs of healthcare, manufacturing, and real estate sectors. Our product range is designed to be safe, breathable, available in eco-friendly options, and suitable for high-volume use. With competitive wholesale pricing, a stable supply, and expert consultation, 8688.vn is a trusted partner that helps businesses implement effective non-woven solutions.

Visit 8688.vn to explore our full product range and find the right solution for your hygiene, operational, and asset protection needs.